![]()

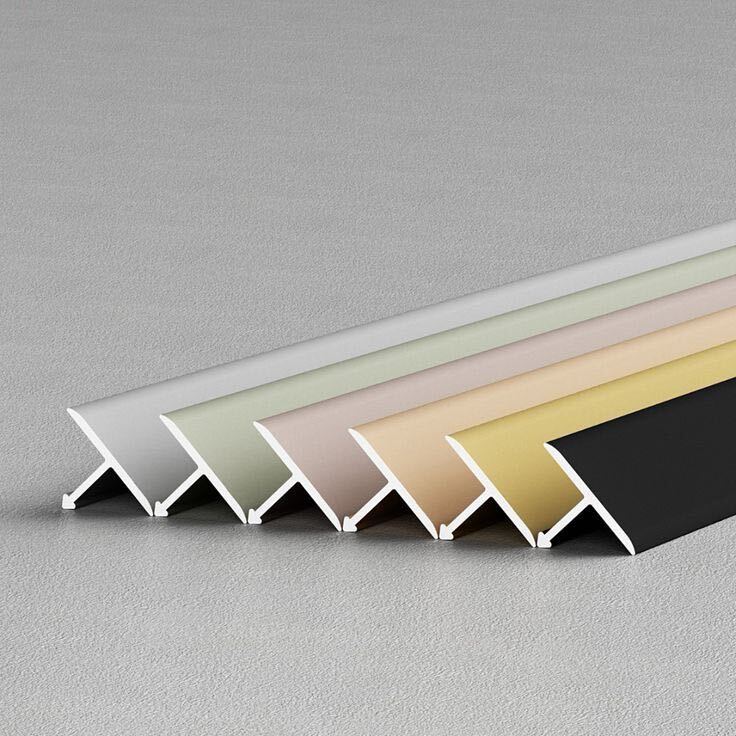

At YONGDAO, our 85,000-square-meter manufacturing base, established in 2010, is more than a collection of 15+ extrusion lines and advanced departments for anodizing, powder coating, and CNC machining. It is the physical foundation upon which we build our true engine of growth: our Product Research & Development Innovation Lab. Here, ideas are transformed into the high-quality, competitively priced aluminum profiles and tile trims that reach over 100 countries worldwide.

The Research & Development Mission: From Market Leader to Future Shaper

With a professional sales team of over 80 people and a track record of exceeding one billion RMB in annual sales, we understand global markets—from Europe and Australia to the Middle East. Our BSCI and SGS certifications are testaments to our reliable standards. Our R&D Lab's mission is to leverage this market intelligence and manufacturing prowess to not just meet current demands but to anticipate and shape future trends. We move beyond efficient production (capable of a 45-day delivery for container orders) to pioneer the next generation of aluminum solutions.

Material & Process Innovation: Adjacent to our anodizing and powder coating factories, the lab focuses on developing new alloy compositions and surface treatment technologies. We experiment with enhanced durability, eco-friendly formulations, and unique finishes that set new industry benchmarks.

Prototyping & Validation: In our connected CNC and mould departments, digital designs become tangible prototypes. These undergo rigorous stress, thermal, and corrosion testing, ensuring every new profile—from complex architectural systems to precision tile trims—exceeds international quality standards before mass production.

Inside the Innovation Hub: Where Vision Takes Shape

At the heart of our R&D process is our team of professional designers, who serve as the critical bridge connecting your concepts to tangible reality. We understand that every project has unique requirements, which is why we offer comprehensive design support from the very beginning.

From Your Blueprint to Ours: Collaborative Custom Design

Our skilled designers work closely with you to understand your specific needs, functional demands, and aesthetic vision for any custom aluminum profile or tile trim. Whether you have a detailed sketch, a reference sample, or just a concept, our team is equipped to translate your ideas into precise, manufacturable plans.

Precision CAD Development & Rapid Prototyping

Leveraging advanced CAD software, our designers create detailed 2D and 3D technical drawings for your approval. This digital blueprint ensures every dimension, tolerance, and functional detail is visualized and agreed upon before any tooling begins. This collaborative, precise process minimizes errors, accelerates development time, and guarantees that the final product perfectly matches your expectation, providing a seamless journey from concept to completion.